Description

Imaging Polarimeter Systems for the automatic measurement of residual stress in transparent materials

Overview

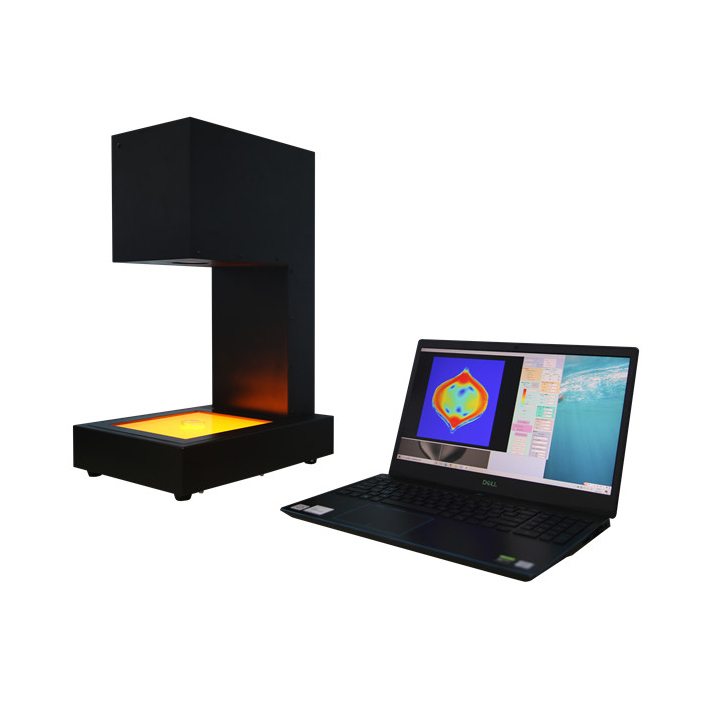

This instrument is a stress measurement device that automatically detects the retardation and the slow axis direction of transparent objects which displays birefringence phenomenon under polarizing light. By inputting sample thickness and phoelastic constant in advance , stress vaule( Mpa) will display automatically.

Application area

glass container, glass vial, water glass, industrial new material glass, optical new material glass, optical lens, crystal, quartz, glass wafer, glass tube, laboratory glassware, float glass plate, automotive glass, resin plate, resin film, mold injection resin products

Measuring principle

When light travels through the polarizer, it becomes circular polarized light. When a stressed sample is placed, there is an optical retardation between the slow axis and fast axis . Thus the outgoing light becomes elliptical polarized light. By rotating the analyzer , the rotating angle of the polarized light which is affected by the presence of internal stress can be detected precisely. By applying the rotating angle to a formula, stress value in the sample will be calculated.

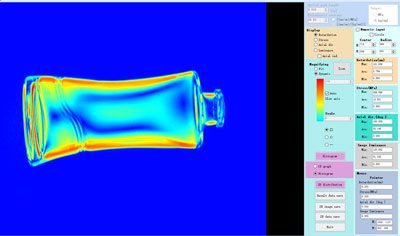

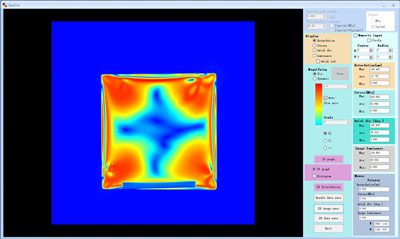

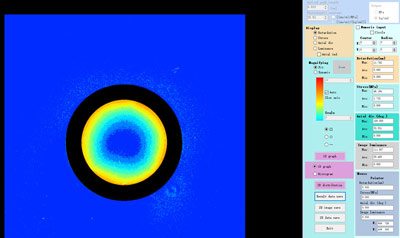

During one measurement, this full-automatic Polariscope can take images at a specialized angle, and simultaneously obtain the stress value and slow axis direction of all sample areas in the viewing field and output the 3D stress distribution.

Application

Glass Inspection

Plastic Inspection

Crystal Inspection

Optical Fiber Inspection

Specifications

Measurement area size: 175*175mm

Measuring space height: 0~150mm

Detection method: rotating analyzer method

Setting wavelength: 590nm

Retardation range: 0-145nm

Repeated measurement accuracy: 1nm

Effective pixels: 1100*1100

Overall size: 363*285*490mm

Weight: 16kg

Light source: high brightness LED

Power supply: AC 100~240V 50/60Hz 0.35A

Support system: Windows10

Use environment: indoor use

Environment temperature: 10℃~40℃

Environmental humidity: 25% ~ 85%

Accessories: measuring main body, PC, cable, power adapte

Features

1.One-key automatic stress measurement within the whole viewing field ;

2.Under high-speed mode , a single measurement can be finished in 15s;

3.The high-speed and standard modes can be switched freely ;

4.When moving the cursor, it will automatically display stress retardation at the point of the cursor ;

5.Strong testing results analysis functions ;

* All testing data ( optical retardation , slow axis angle , stress value) will be stored in CSV format

* For 1 sample , all testing info can be stored in bak format . No need to proceed a second time test

* Data storage , image storage functions . Including below :

– Entire stress image within viewing field

– 3D stress image within viewing field

– Selected area stress image

– Zooming in selected area

Images